1 Ton Cable Drum Production Line Rollers Transfer Carts

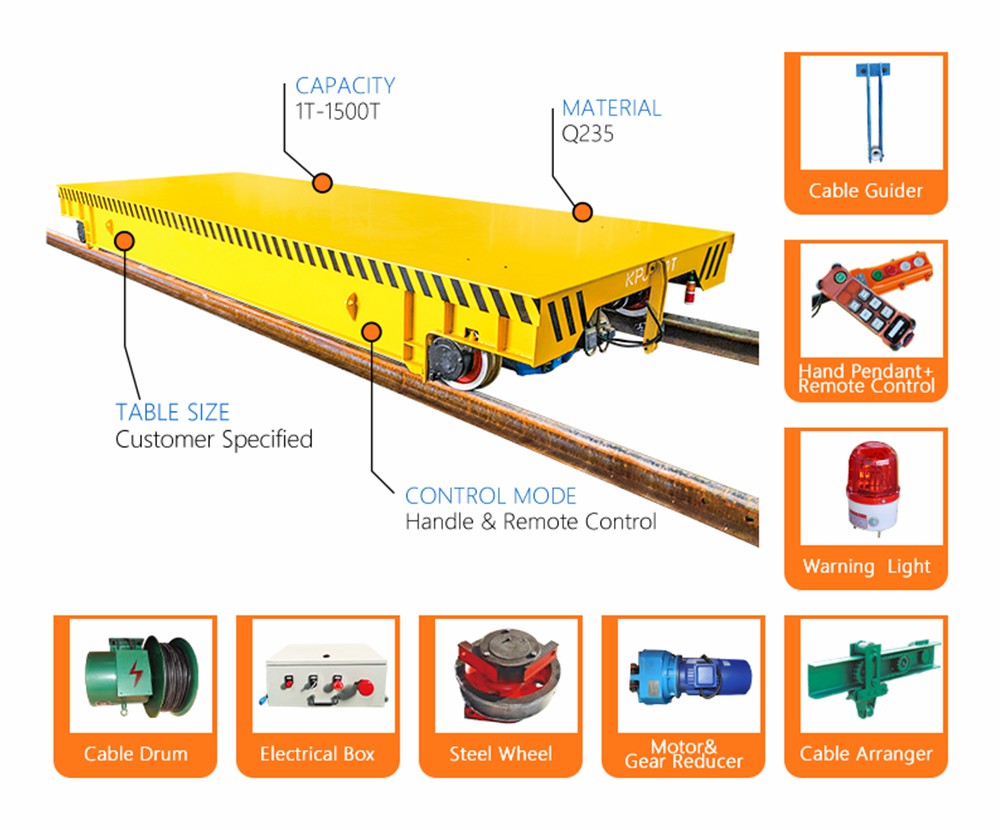

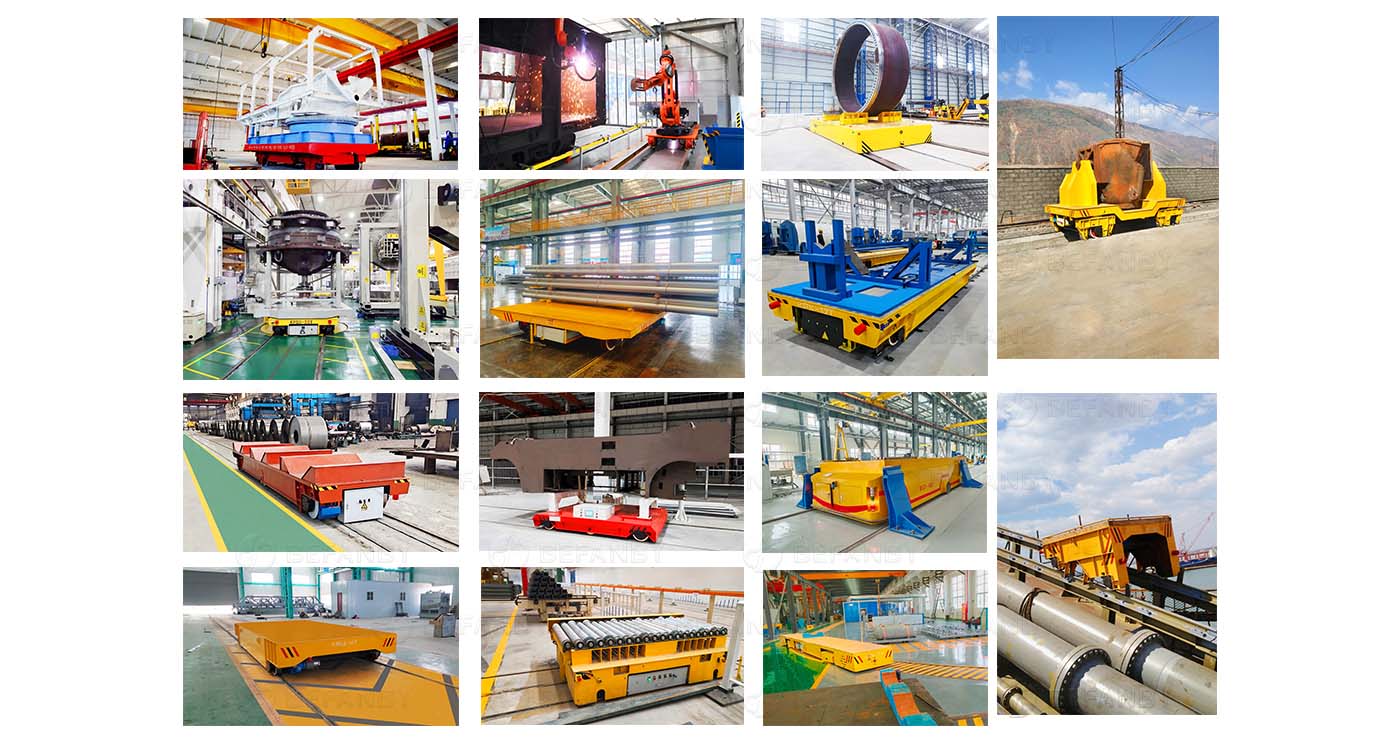

When customizing the rail electric transfer car, the enterprise can choose different parameters such as body material, load capacity, transportation speed, etc. according to its own production and transportation needs to meet different industrial transportation needs. At the same time, the rail electric transfer car can also be upgraded with automation according to customer needs, such as navigation system, obstacle avoidance system, etc., to maximize the intelligence of the equipment.

In addition to customized services, rail electric transfer car manufacturers also provide professional after-sales service to timely discover and solve equipment failures and ensure the normal operation of the equipment.

This rail electric transfer car is equipped with rollers on the car body and used on the factory production line. Among them, the working principle of the roller conveyor is mainly to drive the roller to rotate through the drive device to realize the transportation of materials.

The roller conveyor is mainly composed of a drive device, a roller, and a possible electronic control system. The material is loaded on the roller, and when the drive device is started, it drives the roller to rotate. This rotation acts on the material, causing it to move in the direction of the conveyor. The electronic control system controls the motion program of the conveyor by judging whether the material has reached the specified position, thereby achieving precise material conveying control.

Roller conveyors can be divided into no powered roller conveyors and powered roller conveyors. no powered roller conveyors themselves have no drive device, and the rollers rotate passively. The items are moved by manpower, gravity or external push-pull devices. The powered roller conveyor is equipped with a drive device that can actively drive the roller to rotate, and complete the material conveying through the friction between the roller and the material. The powered roller conveyor can strictly control the running state of the items, and convey the items accurately, smoothly and reliably at the specified speed, which is convenient for realizing the automatic control of the conveying process.

In addition, the design and application of roller conveyors have been quite mature. From completing the conveying within the workshop to completing the material handling within the enterprise, between enterprises and even between cities, it has become an indispensable part of the mechanization and automation of the material handling system. In addition to providing customized services, rail electric transfer car manufacturers also provide professional after-sales services and can install them on site. In order to timely discover and solve equipment failures and ensure the normal operation of the equipment.