20 Tons Lithium Battery Powered Automatic Guided Vehicle

Description

This AGV uses maintenance-free lithium battery function, with a larger number of charge and discharge times and a smaller size.

In addition, the vehicle uses a steering wheel that can change direction in a small space to better meet the use requirements of limited space.Emergency stop buttons are installed at the four corners of this AGV. Operators can actively press them to immediately cut off the power when an emergency is found to reduce the loss of the vehicle caused by collision.

The warning lights of the vehicle are installed in a long strip at the rear of the it, covering an area of 4/5 of the width of the vehicle, with bright colors and greater visibility.

In addition, an LED display screen is installed on the electrical box of the vehicle to help staff more intuitively understand the operating status of the vehicle.

Advantages

AGV have two different control method,first one called remote,which can widen the distance between operator and working space,on it there are a lots of buttons with clearly instrument.The other one called PLC programme,which installed on the vehicle,instruct AGV to perform forward and backward movements by touching the screen with fingers.

Application

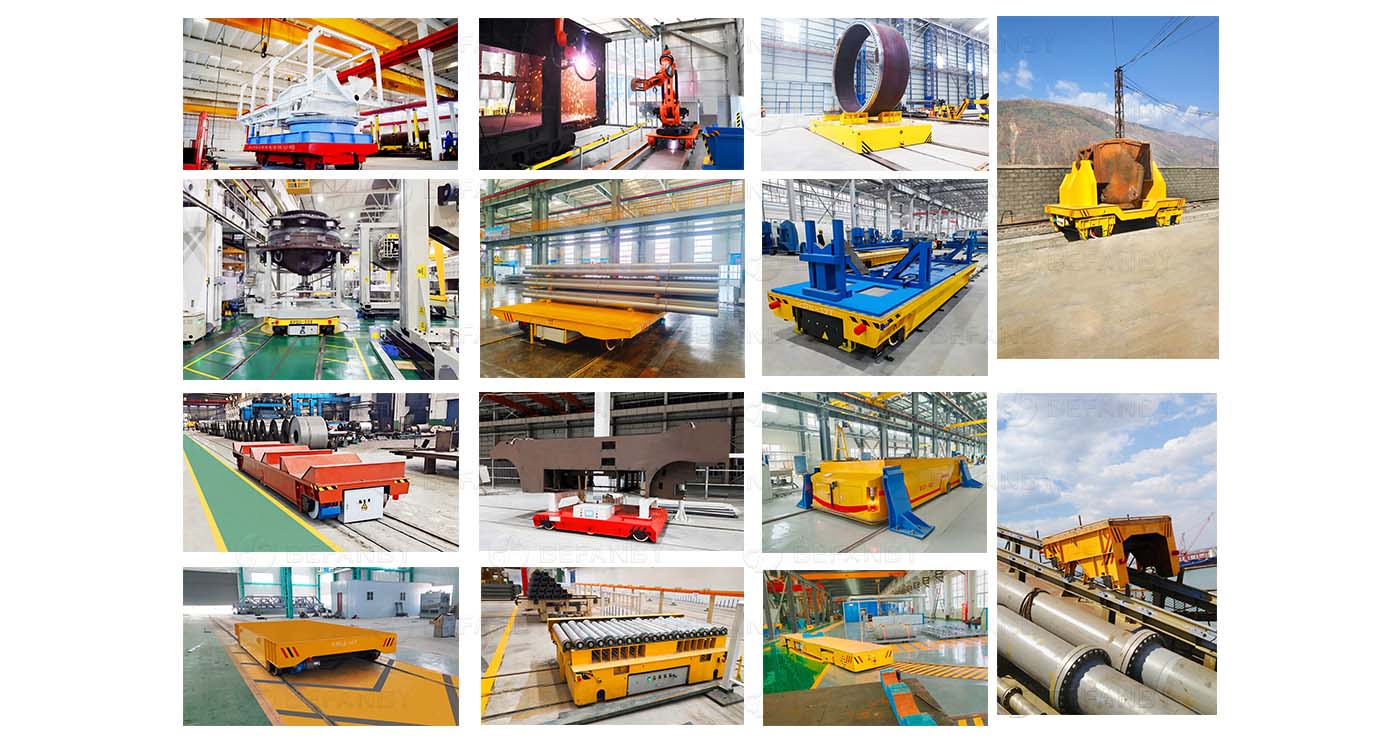

The "20 Tons Lithium Battery Powered Automatic Guided Vehicle" is used in the production workshop for material handling tasks. The AGV works together with the indicator lights in the production workshop to clearly display the location and direction of operation. In addition, the vehicle has no limit on the use distance and can rotate 360 degrees, the steering wheel is flexible. The AGV is cast from steel and has high temperature resistance, so it can be used in a variety of work occasions.

Customized For You

Almost every product of the company is customized. We have a professional integrated team. From business to after-sales service, technicians will participate in the whole process to give opinions, consider the feasibility of the plan and keep following up on the subsequent product debugging tasks. Our technicians can make customized designs according to the specific needs of customers, from power supply mode, table size to load, table height, etc. to meet customer needs as much as possible, and strive for customer satisfaction.