Anti-Explosional Sliding Line Rail Ladle Transfer Trolley

Current transmission to the railcar: Through the electrical connection between the contact and the busbar, the current can be transmitted from the busbar to the railcar. The electrical equipment on the railcar can use this current to perform normal work, such as driving the motor.

Movement of the contact device: When the railcar runs on the track, the contact device moves accordingly with the movement of the railcar. In this way, the electrical connection between the contact and the busbar can be maintained even when the railcar is in operation.

Power supply range of the busbar: The busbar is usually laid along the railway line and parallel to the railcar track. Therefore, the busbar can provide continuous power supply to ensure that the railcar can obtain electrical energy throughout the railway line.

The busbar is made of conductive material, usually copper or aluminum wire. One end is connected to the power supply, and the other end is connected to the equipment or machinery to transmit electrical energy. The rail is a conductive material made of insulating material, usually plastic or rubber. There are usually grooves on the rail for installing the busbar, while ensuring the stable sliding of the busbar. The busbar contacts the rail through devices such as brackets or wheels to achieve the transmission of electrical energy. When the busbar slides on the rail, the contact point between the busbar and the rail forms a circuit, and the current flows to the equipment through the busbar. In general, the working principle of the busbar is to use the circuit formed by the sliding contact point to transmit electrical energy through the contact between the busbar and the rail to achieve control and power supply of the equipment.

In addition, the design of the busbar ladle car rail car also takes safety into consideration, such as opening a cable trench on the side of the track or between the two rails, installing a safety busbar in the cable trench, and laying a cover plate fixed to the ground on one side with a hinge on the cable trench. When the electric flat car is running, the cover plate is lifted up through the trench flap device installed on the flat car. This design not only ensures the continuity of power supply, but also improves the safety of vehicle operation.

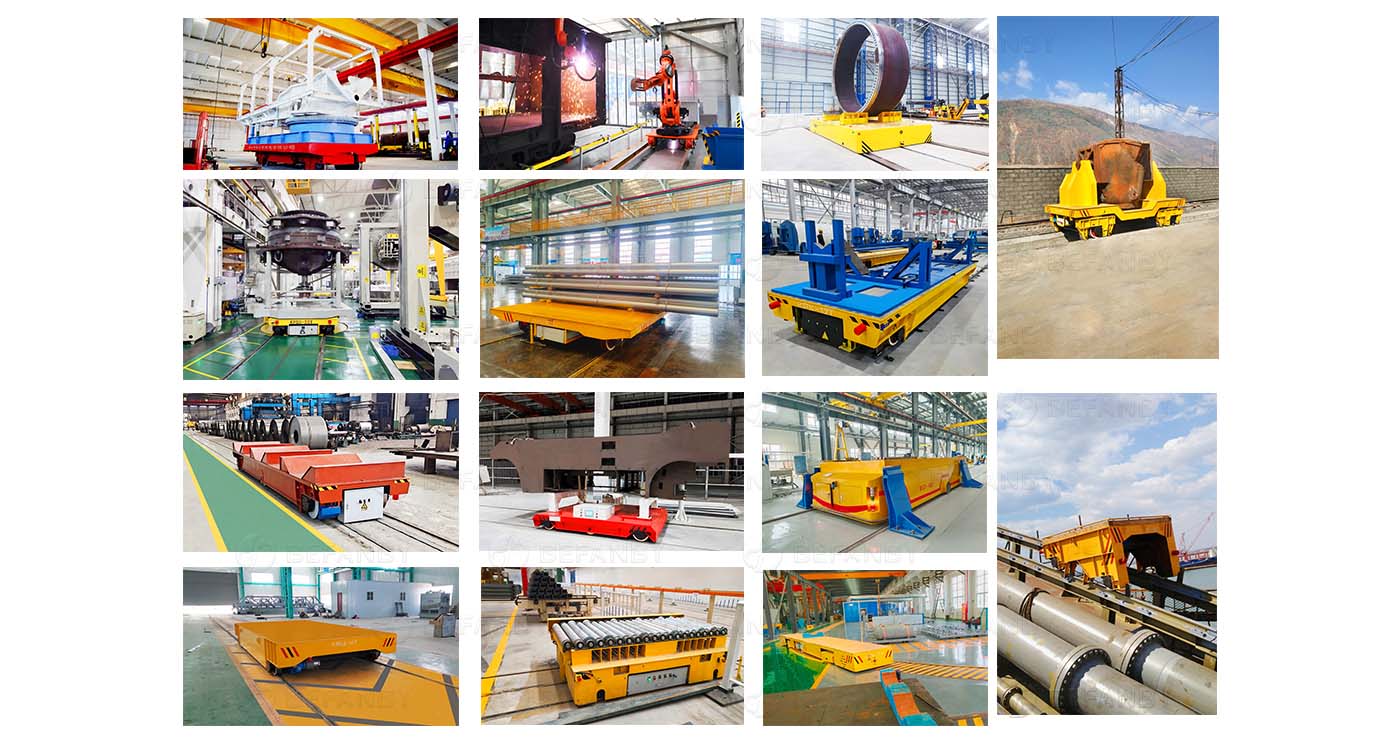

The ladle car is a ladle transfer equipment used for steelmaking. Its main function is to transfer the ladle to the destination and pour the molten steel in the ladle into the steel mold through special equipment. Ladle cars are divided into track-type ladle cars and trackless ladle cars in terms of structure. They can be divided into battery-type, low-voltage rail power supply, busbar, etc. in terms of power supply mode.

Ladle cars are very important for the steel industry because they can greatly improve the efficiency of steelmaking, thereby reducing production cycles and costs. Not only do they need to have good high temperature resistance and stability, but they also need to have excellent corrosion resistance. Ladle cars play a very important role in the steelmaking industry. Their appearance has greatly improved the production efficiency and quality of steelmaking. The design and manufacturing of ladle cars are very complex and require a high level of technology and quality assurance.