Customized Rail Powered V-Deck Frame Transfer Cart

Applications

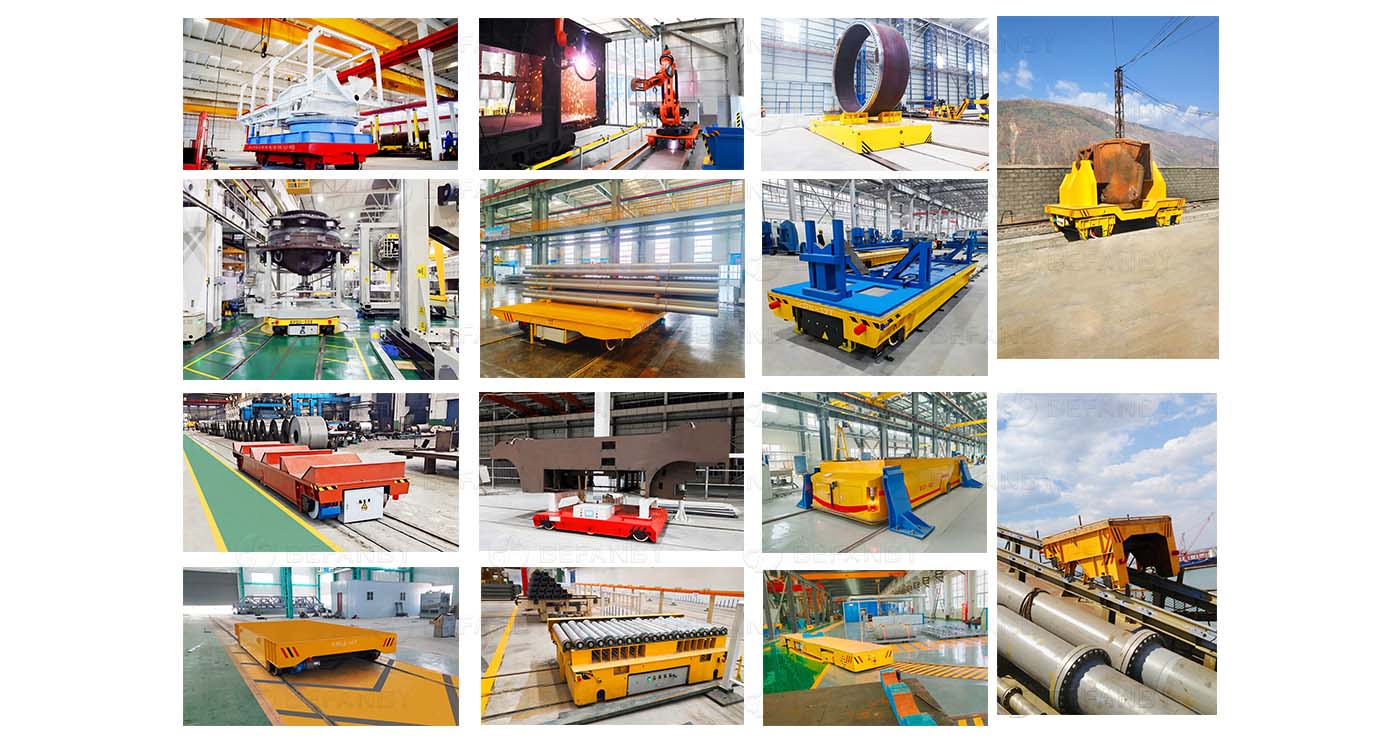

The application occasions of rail electric transfer carts are mainly heavy material handling in large factories and workshops, such as steel mills handling steel, machinery plants handling large mechanical parts, etc. These transfer carts rely on rails to travel, have clear directions, are not easy to deviate from the route, have large carrying capacity, and can be designed with different carrying tonnages according to different needs. Because its power system is relatively stable and can run continuously for a long time, it is suitable for places with fixed transportation routes and large transportation volumes.

Support Customized

Low-voltage rail-powered coil conveying rail transfer carts generally install V-frames and roller frames on the workbench as auxiliary functions, which are generally used to prevent round workpieces from rolling or fixing workpieces. Some are used in spray painting and sandblasting rooms to roll workpieces to achieve automatic rolling of workpieces, thereby achieving better polishing and painting effects.

The V-frame installed on the workbench of this rail transfer cart is installed according to customer needs. It is divided into detachable and non-detachable types. The non-detachable one can only pull coils and is rarely used. The detachable coil transport vehicle can be disassembled at any time. When you need to pull coils, use the V-frame. When you don't pull coils, such as pulling some plates or other workpieces, you can remove the V-frame. In this way, you can achieve the function of one car for multiple uses, which is more flexible and convenient.

Products Features

1. Improve efficiency: Material handling equipment can greatly improve the efficiency of logistics operations. Through mechanization, it avoids labor, shortens the operation time, and greatly improves the operation efficiency.

2. Reduce costs: Using material handling equipment can reduce labor costs. Compared with manual handling, the investment and maintenance costs of material handling equipment are higher, but in the long-term use process, it can reduce labor costs and save human resources.

3. Improve operation quality: Material handling equipment can ensure the integrity and accuracy of materials during transportation and handling, and avoid material damage or errors caused by human factors.

4. Diversification: The types and functions of material handling equipment are very diverse, and different equipment can be selected according to needs.

5. Automation: With the development of science and technology and the advancement of automation technology, the automation level of material handling equipment is getting higher and higher, and automation equipment helps to improve work efficiency and accuracy.

6. High reliability: The mechanical part and control system of material handling equipment are made of high-quality materials and technology, with high reliability and stability.

Practical Application

Material handling equipment is an important tool for modern logistics and production. Its basic characteristics are to improve efficiency, reduce costs, and improve work quality. Through the combination of different material handling equipment and application scenarios, the efficiency and quality of enterprise logistics and production can be greatly improved, and industrial upgrading and transformation and upgrading can be promoted.