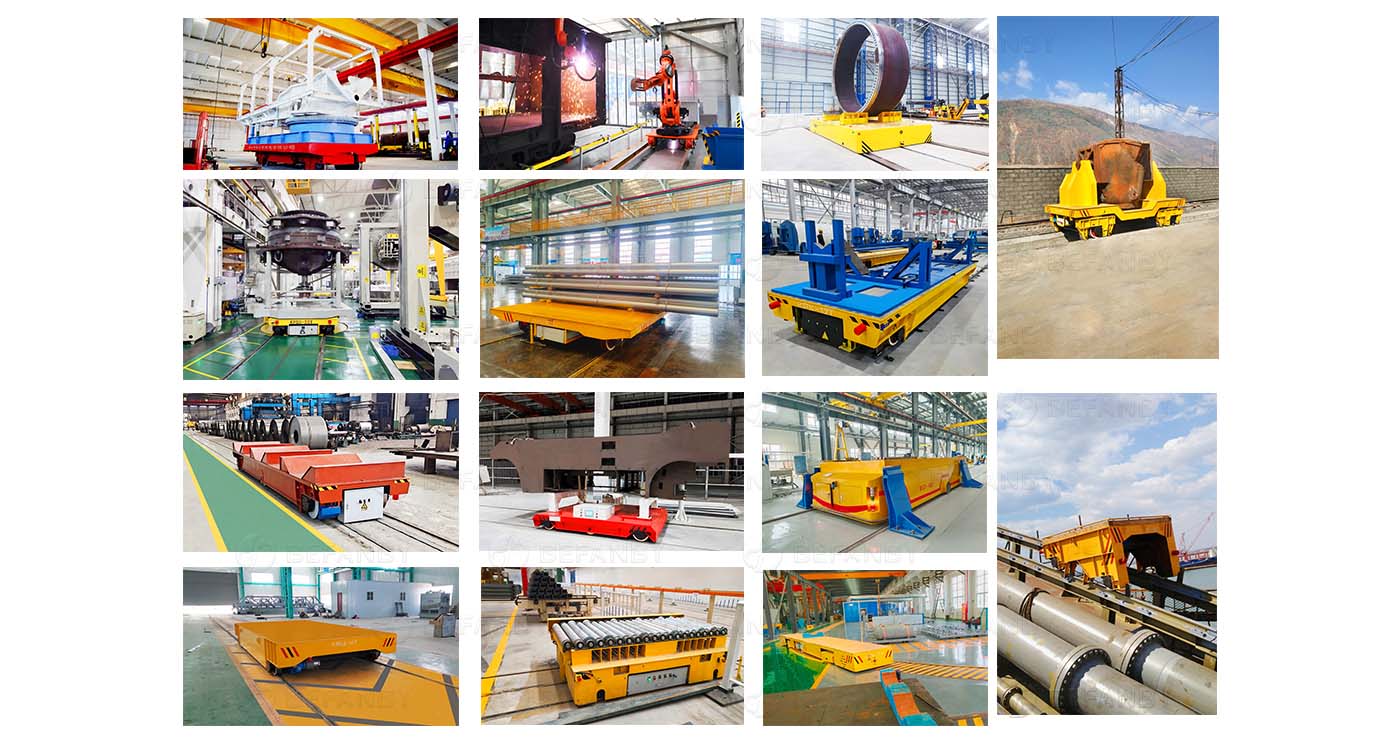

Customized Table Size Track Flatbed Transfer Cart

Safety system

Safety is one of the core considerations of rail electric transfer cars. This system not only ensures the safety of operators, but also prevents accidents caused by equipment failure. The safety system of rail electric transfer cars usually includes:

Overload protection: This function can monitor the load on the transfer car. If it exceeds the rated load, the system will automatically trigger an alarm and limit the continued operation of the transfer car, effectively preventing accidents.

Emergency braking: In the event of an emergency, the operator can quickly stop the transfer car by pressing the emergency brake button to avoid potential safety risks.

Safety sensing device: Devices such as infrared sensors and impact sensors are used to monitor the environment around the transfer car. Once an obstacle is detected, the transfer car will stop automatically.

Through a series of safety measures, rail electric transfer cars ensure safety and reliability in any environment, ensuring the smooth progress of production and operation.

Drive system

The drive system is the ""brain"" of the rail electric transfer car, responsible for converting electrical energy into mechanical energy to drive the operation of the transfer car. The system has the following key components:

Motor: The motor is the core component of the drive system and can provide sufficient power to meet the operating requirements under different load conditions. The choice of motor directly affects the operating speed and carrying capacity of the transfer car.

Speed change device: Through the speed change device, the operator can adjust the operating speed of the transfer car as needed to adapt to different transportation tasks. This flexibility allows rail electric transfer cars to be easily used in various industrial environments.

By optimizing the design of the drive system, rail electric transfer cars can achieve efficient and low-energy transportation, which also effectively reduces the operating costs of enterprises.

Power system

The power system is responsible for providing continuous and stable power for rail electric transfer cars. The components of the system include:

Battery pack: The high-performance battery pack can provide long working time while supporting fast charging to meet the needs of high-intensity working environments.

Charging system: The intelligent charging system can monitor the status of the battery in real time and automatically adjust the charging method according to different charging needs to ensure the life and safety of the battery.

The efficient operation of the power system not only improves the working time of the rail electric transfer car, but also significantly improves the logistics efficiency of the enterprise.

According to the needs of different enterprises, the rail electric transfer car can be customized in various forms. This flexibility enables enterprises to formulate logistics solutions that suit their needs according to the actual situation on site. Customization options include:

Load specifications: Different industrial fields have different requirements for transportation loads. The rail electric transfer car can be customized with different load specifications according to the production needs of the enterprise, ranging from a few tons to tens of tons, to meet the needs of various production scenarios.

Size and structure: According to the actual space of the factory, the length, width and height of the rail electric transfer car can be customized to ensure smooth access to narrow operating environments. At the same time, the structural design can also be adjusted for specific purposes, such as adding pallet brackets or container fixtures.

Professional after-sales team support

Installation and commissioning: When the rail electric transfer car is delivered to the enterprise, the after-sales team will send professional technicians to the site to install and debug the equipment. They will ensure that the equipment works properly according to the design standards and promptly identify and solve potential problems.

Regular maintenance and inspection: In order to ensure the long-term and efficient operation of the rail electric transfer car, the after-sales service team will regularly maintain and inspect the equipment, replace wearing parts in time, and ensure uninterrupted production. Through regular maintenance, the service life of the equipment can be effectively extended and the company's investment can be protected.

As an important tool for modern logistics and transportation, the rail electric transfer car meets the needs of various industries for logistics and transportation with its high efficiency, safety and flexibility. Through detailed composition analysis, customized options and perfect after-sales service, we can see that the rail electric transfer car not only optimizes the operating efficiency of the enterprise, but also provides a strong guarantee for safe production.