Factory mold transport trackless transfer trolley manufacturer

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for Factory mold transport trackless transfer trolley manufacturer, Our concept is usually to aid presenting the confidence of each purchasers with the offering of our most honest provider, and the right product.

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for mold transfer trolley, Trackless Transfer Trolley, Our goods have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we have been sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

Advantage

Electric trackless transfer carts have many advantages:

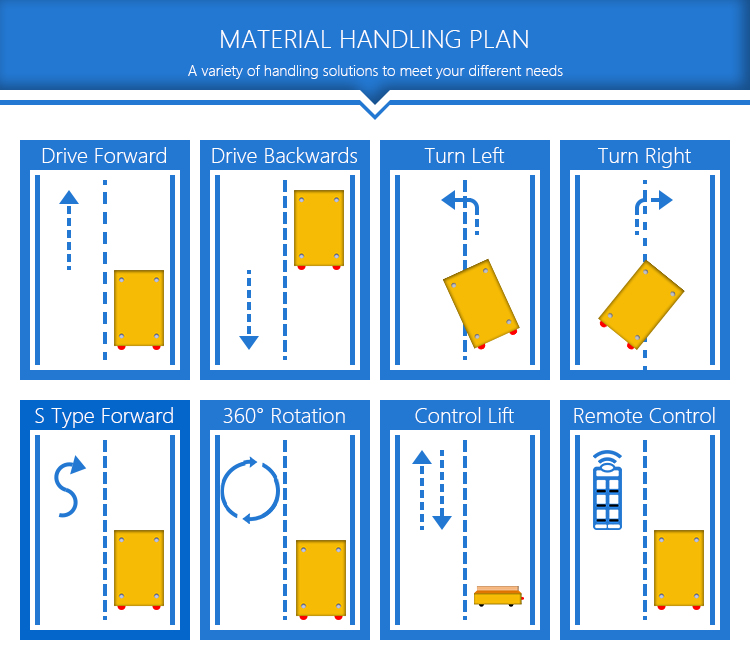

1.Not only does it operate without restrictions, but it can also turn 360° in place to adapt to a narrower space.

2.The use of imported polyurethane wheels can ensure that the ground is not damaged.

3.Functions such as 360-degree protection without dead ends and automatic stop in case of people ensure safety issues during the operation of the electric trackless transfer cart.

4.The operation design is more user-friendly, and you can use the handle, remote control, touch screen, and joystick operation methods.

Application

Application areas: metallurgy and mining, shipbuilding, mold stamping, cement plants, steel deployment, transportation and assembly of large machinery and equipment, etc.

They have the characteristics of high performance, low noise, no pollution, flexible operation, safety and convenience.

Technical Parameter

| Technical Parameter of BWP Series Trackless Transfer Cart | ||||||||||

| Model | BWP-2T | BWP-5T | BWP-10T | BWP-20T | BWP-30T | BWP-40T | BWP-50T | BWP-70T | BWP-100 | |

| Rated Load(T) | 2 | 5 | 10 | 20 | 30 | 40 | 50 | 70 | 100 | |

| Table Size | Length(L) | 2000 | 2200 | 2300 | 2400 | 3500 | 5000 | 5500 | 6000 | 6600 |

| Width(W) | 1500 | 2000 | 2000 | 2200 | 2200 | 2500 | 2600 | 2600 | 3000 | |

| Heigth(H) | 450 | 500 | 550 | 600 | 700 | 800 | 800 | 900 | 1200 | |

| Wheel Base(mm) | 1080 | 1650 | 1650 | 1650 | 1650 | 2000 | 2000 | 1850 | 2000 | |

| Axle Base(mm) | 1380 | 1680 | 1700 | 1850 | 2700 | 3600 | 2850 | 3500 | 4000 | |

| Wheel Dia.(mm) | Φ250 | Φ300 | Φ350 | Φ400 | Φ450 | Φ500 | Φ600 | Φ600 | Φ600 | |

| Wheel Quantity(pcs) | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 6 | 8 | |

| Ground Clearance(mm) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 75 | 75 | |

| Running Speed(mm) | 0-25 | 0-25 | 0-25 | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 | 0-18 | |

| Motor Power(KW) | 2*1.2 | 2*1.5 | 2*2.2 | 2*4.5 | 2*5.5 | 2*6.3 | 2*7.5 | 2*12 | 40 | |

| Batter Capacity(Ah) | 250 | 180 | 250 | 400 | 450 | 440 | 500 | 600 | 1000 | |

| Battery Voltage(V) | 24 | 48 | 48 | 48 | 48 | 72 | 72 | 72 | 72 | |

| Running Time When Full Load | 2.5 | 2.88 | 2.8 | 2.2 | 2 | 2.6 | 2.5 | 1.8 | 1.9 | |

| Running Distance for One Charge(KM) | 3 | 3.5 | 3.4 | 2.7 | 2.4 | 3.2 | 3 | 2.2 | 2.3 | |

| Max Wheel load(KN) | 14.4 | 25.8 | 42.6 | 77.7 | 110.4 | 142.8 | 174 | 152 | 190 | |

| Reference Wight(T) | 2.3 | 3.6 | 4.2 | 5.9 | 6.8 | 7.6 | 8 | 12.8 | 26.8 | |

| All trackless transfer carts can be customized, free design drawings. | ||||||||||

Handling methods

Handling methods

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for factory mold transport trackless transfer trolley, Our concept is usually to aid presenting the confidence of each purchasers with the offering of our most honest provider, and the right product.

A factory mold transport trackless transfer trolley is a type of material handling equipment used to move heavy loads such as factory molds within a factory or workshop without using a fixed track. They are often used in automated manufacturing, assembly lines, and logistics systems to transport materials.

These transfer trolleys often come with features such as remote control options, safety features, and various load capacity options to suit different applications. Some trackless transfer trolleys are powered by batteries, while others may use electricity, compressed air, or other forms of energy.

When selecting a trackless transfer trolley for factory mold transport, it is important to consider the weight and dimensions of the molds, the distance the trolley will need to travel, the terrain and environment within the factory or workshop, and safety regulations and requirements.

The trrackless transfer trolley, manufacturered by BEFANBY. Our goods have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we have been sincerely looking forward to cooperating with more overseas customers based on mutual benefits.