Heavy Duty Mold Plant Battrey Railless Transport Trolley

Heavy Duty Mold Plant Battrey Railless Transport Trolley,

10ton transfer cart, 20t handling vehicle, Intelligent Transfer Cart, Manual Transfer Carts, Transfer Bogie,

description

When it comes to the handling of heavy items, battery trackless transfer carts are a very ideal solution.This technologically advanced equipment has a load capacity of 50 tons and can provide efficient, safe and reliable logistics solutions in the industrial field.This article will discuss in detail the advantages, working principles and applicable scenarios of battery trackless transfer carts to help you understand and upgrade your logistics solutions.

Working Principle

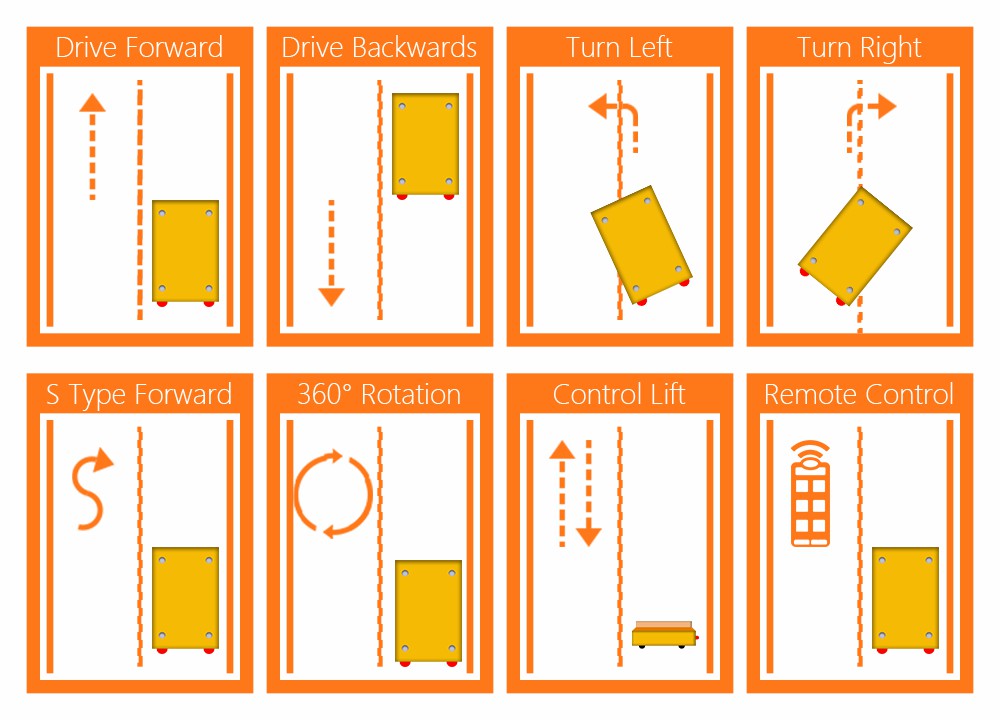

Battery trackless transfer carts are powered by batteries and move through a variety of drive systems.The main drive systems include DC motor drive, AC motor drive and gear drive.According to different work scenarios and needs, users can choose the appropriate driving method.

The battery is connected to the electric motor through a hard connector to provide power for the battery trackless transfer cart.The intelligent control system receives the operator’s instructions and sends a signal to the motor through the controller to control the operation and steering of the trackless transfer cart.According to needs, a touch screen or remote control can be selected to achieve more convenient control.

Application

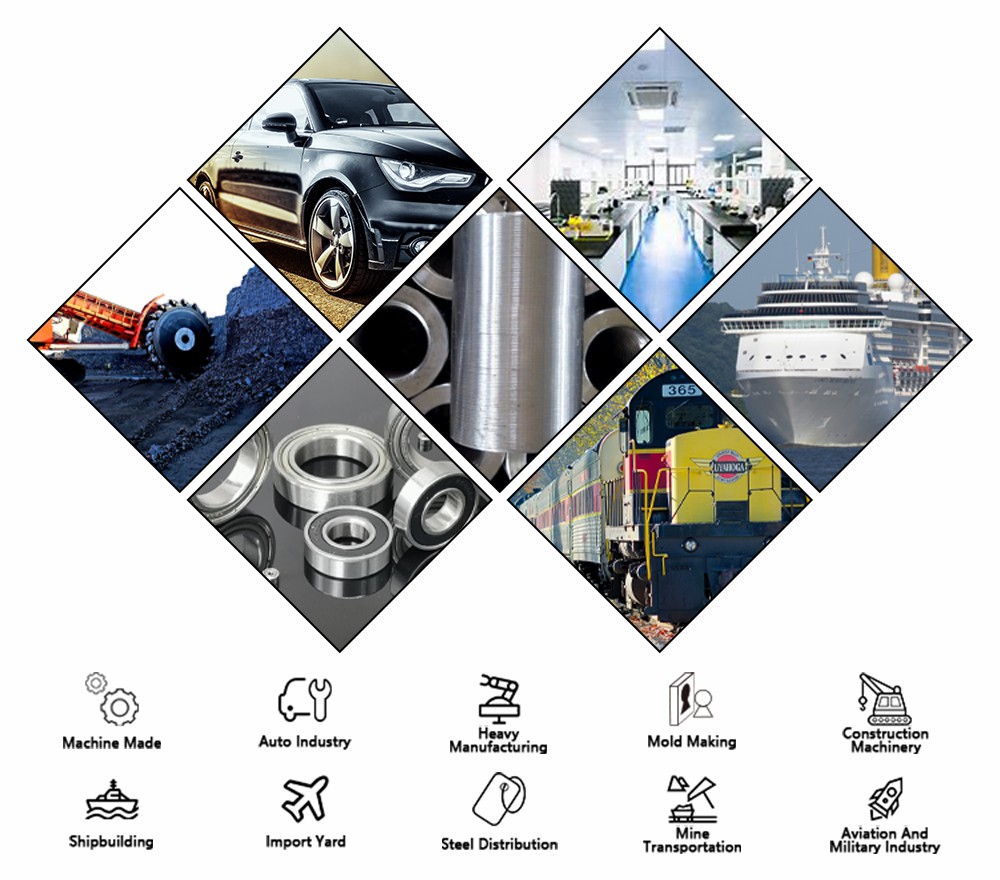

Battery trackless transfer carts are widely used in heavy industries such as iron and steel, metallurgy, automobile manufacturing, aerospace, etc.The following are some examples of applicable scenarios:

1. Steel plant: used to transport heavy goods such as steel and steel pipes to reduce the risk and labor intensity of human handling.

2. Automobile manufacturing plant: used to transport heavy-duty parts such as automobile bodies and engines to improve production efficiency and logistics punctuality.

3. Machinery manufacturing plant: used to transport large-scale machinery and equipment, replacing traditional lifting equipment, saving costs and space.

4. Aerospace industry: Used to transport heavy items such as aviation engines and aircraft parts to ensure the safety and efficiency of equipment.

Advantage

Compared with traditional fuel-powered conveying tools, 30t battery power electric platform carts have many advantages.

First of all, 30t battery power electric platform carts, with their green and environmentally friendly characteristics, are in line with the current development direction of energy conservation and emission reduction, and sustainable development has become the consensus of the industry.

Secondly, the noise of battery power electric platform carts is lower, noise pollution is reduced during transportation, and the comfort of the working environment is improved.

In addition, 30t battery power electric platform carts have higher carrying capacity and transportation efficiency, which can meet the growing needs of the logistics industry.

Why Choose Us

Source Factory

BEFANBY is a manufacturer, there is no middleman to make the difference, and the product price is favorable.

Customization

BEFANBY undertakes various custom orders.1-1500 tons of material handling equipment can be customized.

Official Certification

BEFANBY has passed ISO9001 quality system, CE certification and has obtained more than 70 product patent certificates.

Lifetime Maintenance

BEFANBY provides technical services for design drawings free of charge; the warranty is 2 years.

Customers Praise

The customer is very satisfied with BEFANBY’s service and looks forward to the next cooperation.

Experienced

BEFANBY has more than 20 years of production experience and serves tens of thousands of customers.

Do you want to get more content?

Material Handling Equipment Designer

BEFANBY have involved in this field since 1953

+

YEARS WARRANTY

+

PATENTS

+

EXPORTED COUNTRIES

+

SETS OUTPUT PER YEAR

LET’S START TALKING ABOUT YOUR PROJECT

Material handling trucks are indispensable and important equipment in modern industrial production, playing a decisive role in factories, warehouses, ports and other scenarios. Compared with traditional handling methods, material handling vehicles do not need to lay tracks, their running distance is not limited, and their load-bearing weight can be customized, which brings huge convenience and benefits to enterprises.

Traditional trucks need to rely on laid tracks to operate, which limits their flexibility and applicable fields. The material handling vehicle uses autonomous navigation technology and can travel freely without tracks, thus adapting to various complex working environments. Whether it is a small warehouse space or a vast production site, material handling trucks can easily cope with various carrying tasks.

Different businesses have different material handling needs, some need to carry lighter items, while others need to move heavy equipment. Traditional trucks have limited carrying capacity and cannot meet different needs. The material handling truck can be customized according to the load capacity and can easily handle the handling tasks of different materials. Whether it’s small parts or large machinery, material handling trucks can get the job done.

The material handling vehicle is equipped with an advanced intelligent navigation and positioning system, which can realize autonomous obstacle avoidance and path planning, effectively reducing the risk of human operation. The operator only needs to set simple instructions, and the material handling vehicle can automatically complete the transportation task according to the predetermined path, greatly improving work efficiency and safety. At the same time, material handling vehicles can also be interconnected with other equipment to realize automated production lines and further improve overall production efficiency.