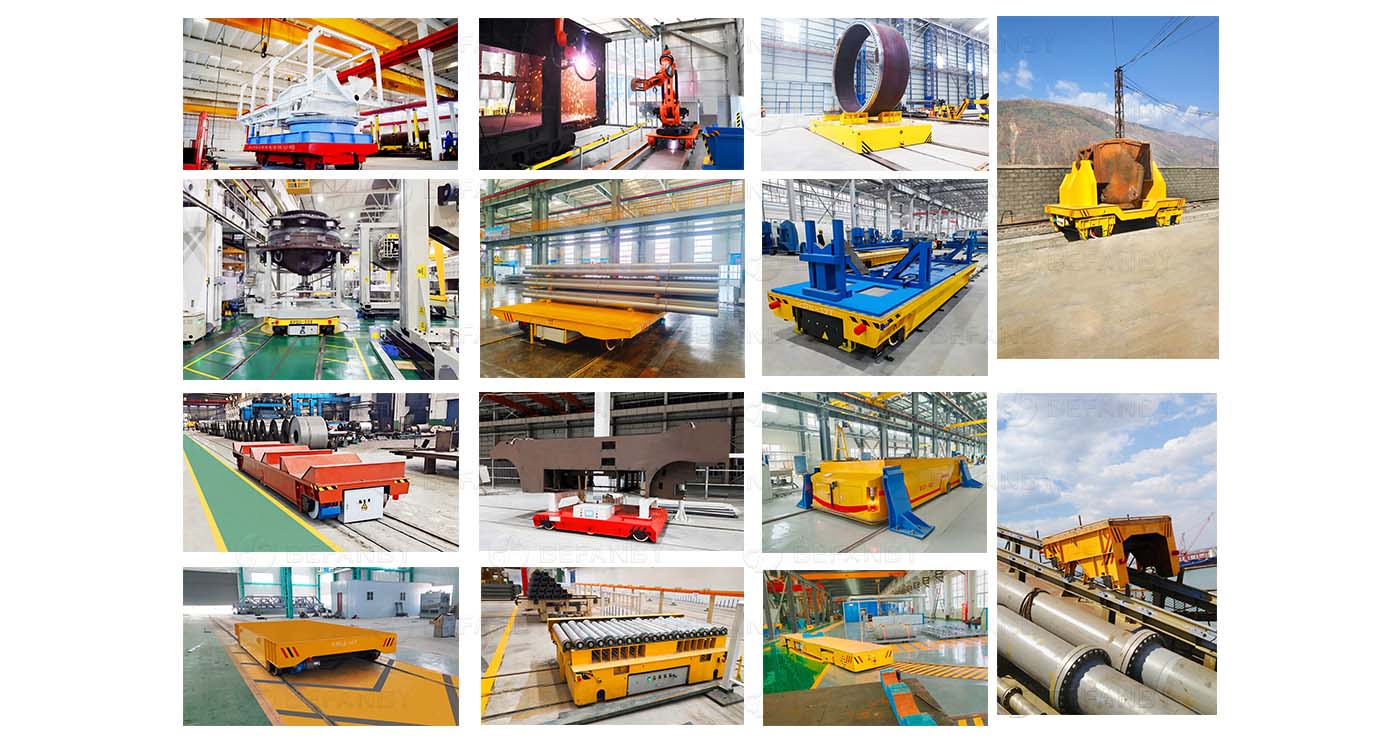

Heavy load 20T Cylindric Objects Battery Guided Carts

Description

First of all, the rail laying of material handling vehicles is a crucial link. Reasonable rail layout can make material handling vehicles more stable and efficient during work. When choosing rail materials, their load-bearing capacity, wear resistance and service life should be considered. Generally speaking, steel rails are a common and reliable choice that can meet a variety of material handling needs.

Smooth Rail

Secondly, low-voltage rail power supply is a major feature of modern material handling vehicles. Compared with traditional high-voltage power supply, low-voltage power supply is not only safe and stable, but also can reduce energy consumption and reduce safety hazards. Material handling vehicles powered by low-voltage rails can be more energy-efficient and efficient during work, saving costs for enterprises and improving production efficiency.

Strong Capacity

For some special places and needs, customized turning vehicles have become an attractive option. By customizing the turning vehicle according to specific requirements, it can better adapt to various working environments and improve the flexibility and applicability of the transport vehicle. Customized turning vehicles can not only meet the handling needs in narrow spaces, but also achieve precise handling in complex environments, bringing convenience to material handling operations.

Customized For You

In summary, the importance of laying rails for material handling vehicles is self-evident. Choosing appropriate rail materials, using low-voltage rail power supply, and customizing turning vehicles can effectively improve the efficiency and safety of material handling vehicles at work. Whether in production workshops, storage places or logistics centers, high-quality material handling vehicles can bring considerable benefits and advantages to the company's logistics operations.