High payload Trackless Battery Transfer Cart

Bear “Customer initial, High-quality first” in mind, we perform closely with our clients and provide them with efficient and specialist expert services for High payload Trackless Battery Transfer Cart, “Quality”, “honesty” and “service” is our principle. Our loyalty and commitments remain respectfully at your support. Speak to Us Today For even more facts, get in touch with us now.

Bear “Customer initial, High-quality first” in mind, we perform closely with our clients and provide them with efficient and specialist expert services for Battery Driven Rail Trolley, Guided Cart, Manual Transfer Carts, Rail Transfer Trolley, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to offer more quality goods and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

description

The iron and steel industry has always been one of the pillar industries of the national economy, and its production process requires a lot of material transportation and finished product output.In order to improve transportation efficiency and reduce production costs, steel mills generally use trackless transfer carts as the main means of transportation of materials and products.In particular, the 25-ton trackless transfer cart, with its efficient and flexible characteristics, has become a weapon for steel mills.

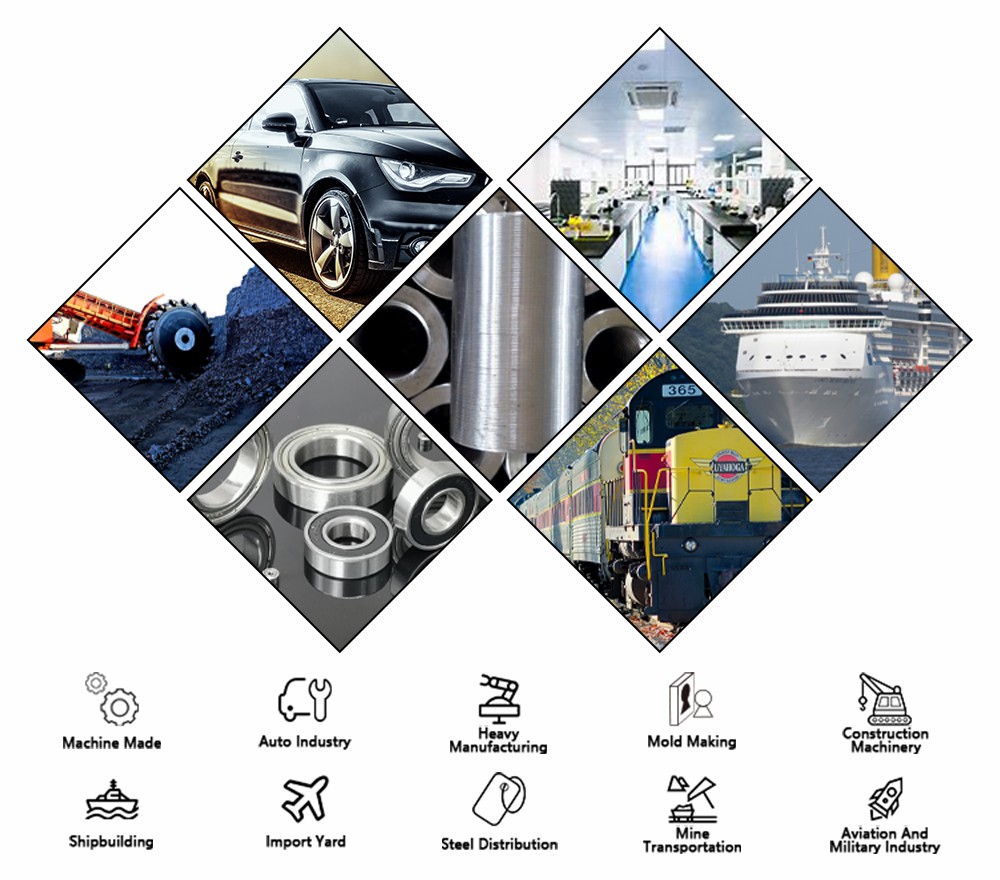

Application

Trackless transfer carts are widely used in steel mills, mainly for the transportation of raw materials and the output of finished products.In terms of raw material transportation, steel mills require a large amount of pig iron, steel materials and various ores in the production process.The 25-ton trackless transfer cart can carry a large load. By connecting with the production line, the raw materials are transported from the warehouse or mine to the production line, which realizes efficient material supply.In terms of finished product output, the steel and other finished products produced by steel mills need to be transported out of the factory in time and supplied to customers.The 25-ton trackless transfer cart can transport the finished product from the production line to the warehouse or specific loading point, and then to the logistics center or customer.

Advantage

Compared with traditional forklifts, 25-ton trackless transfer carts have many advantages.

First of all, the trackless transfer cart can walk along a pre-set lane without interfering with other work in the site, greatly improving the accuracy of material handling and finished product delivery.

Secondly, the trackless transfer cart can realize automated operation. Through the equipped laser navigation and automatic charging system, there is no need for manual operation, saving human resources and operating costs.In addition, the 25-ton trackless transfer cart has a large load capacity and can carry large quantities of materials or finished products at once, improving production efficiency and economic benefits.

Moreover, trackless transfer carts have good handling performance and flexibility, and can adapt to different working environments and site needs.

Characteristic

The 25-ton trackless transfer cart is an electric transfer cart with a simple and compact structure and an energy-efficient battery-powered system.The main body of a trackless transfer cart is composed of a body and a chassis, and the chassis is equipped with steel rails, which realize the handling of materials and products by walking on the steel rails.Trackless transfer carts are usually equipped with manual and automatic control systems, which are simple and convenient to operate.The roads in steel mills are also usually paved with steel rails to facilitate the walking and steering of transfer carts.

Why Choose Us

Source Factory

BEFANBY is a manufacturer, there is no middleman to make the difference, and the product price is favorable.

Customization

BEFANBY undertakes various custom orders.1-1500 tons of material handling equipment can be customized.

Official Certification

BEFANBY has passed ISO9001 quality system, CE certification and has obtained more than 70 product patent certificates.

Lifetime Maintenance

BEFANBY provides technical services for design drawings free of charge; the warranty is 2 years.

Customers Praise

The customer is very satisfied with BEFANBY’s service and looks forward to the next cooperation.

Experienced

BEFANBY has more than 20 years of production experience and serves tens of thousands of customers.

Do you want to get more content?

Material Handling Equipment Designer

BEFANBY have involved in this field since 1953

+

YEARS WARRANTY

+

PATENTS

+

EXPORTED COUNTRIES

+

SETS OUTPUT PER YEAR

LET’S START TALKING ABOUT YOUR PROJECT

Trackless electric transfer car is a new type of factory transportation and handling equipment. Unlike traditional rail-type logistics equipment, it does not require laying rails and can run freely in different venues. This transfer car uses electric drive technology to drive the wheels to run. This can solve the various difficulties and limitations of laying tracks and greatly reduce the operating costs of the equipment.

Polyurethane rubber-coated wheels are key components on trackless electric transfer cars and have good anti-slip and wear resistance. The surface of this wheel is made of special polyurethane material, which can effectively increase friction and make the transfer car more stable during operation. At the same time, this polyurethane material also has good wear resistance and can extend the service life of the wheel.

Trackless electric transfer cars have a wide range of applications in logistics and transportation. They can be used for raw material handling, semi-finished product transportation and finished product delivery within the factory. At the same time, they can also be used in ports, airports and other places to transport containers and goods. Since it does not require laying rails, there are no restrictions on the running route, which is very flexible and convenient.

In short, trackless electric transfer cars are an advanced handling equipment with many advantages and application prospects. By using polyurethane coated wheels, the performance and quality of the transfer car can be further improved, making it safer, more stable and durable during operation.