Motorized Industry Rail Transfer Cart Turntable

description

The motorized industry rail transfer cart turntable used in the factory is a very important device. It has the characteristics of flexible rotation, installation of tracks, docking, and movement of rail transfer carts to the turntable.Through reasonable installation and application, the rail transfer cart turntable can realize the efficient connection of the factory production process and the rapid transportation of materials.However, while using the rail transfer cart turntable, the factory also needs to fully consider safety and carry out regular maintenance and inspections.Only in this way can we ensure that the turntable produces the best results in factory production.

Application

In the production process of the factory, the motorized industry rail transfer cart turntable can be applied to multiple links.For example, in the raw material supply phase, the motorized industry rail transfer cart turntable can be used to transfer raw materials from the supply vehicle to the production line to achieve seamless connection.In the production process, the motorized industry rail transfer cart turntable can be used as a transfer table, so that products from different processes can be moved on the motorized industry rail transfer cart turntable for further processing and assembly.In the outbound stage of finished products, the motorized industry rail transfer cart turntable also plays an important role in transferring finished products from the production line to the packaging and transportation area.

Safety

In the application of motorized industry rail transfer cart turntables, safety is one of the most important considerations.The factory needs to ensure that the operation of the turntable is safe and reliable to avoid accidents.Therefore, motorized industry rail transfer cart turntables are usually equipped with safety devices, such as protective barriers, safety limit switches, etc.In addition, the factory also needs to regularly maintain and inspect the motorized industry rail transfer cart turntable to ensure its normal operation and extend its service life.

Video Showing

Founded In

Production Capacity

Export Countries

Patent Certificates

Our Factory

BEFANBY has an annual production capacity of more than 1,500 sets material handling equipment, which can carry 1-1,500 tons of workpieces. With more than 20 years of experience in the design of electric transfer carts, it already has the unique advantages and mature technology of designing and producing heavy-duty AGV and RGV.

The main products include AGV (heavy duty), RGV rail guided vehicle,monorail guided vehicle, electric rail transfer cart, trackless transfer cart, flatbed trailer, industrial turntable and other eleven series. Including conveying, turning, coil, ladle, painting room, sandblasting room, ferry, hydraulic lifting, traction, explosion-proof and high temperature resistant, generator power, railway and road tractor, locomotive turntable and other hundreds of handling equipment and a variety of transfer cart accessories. Among them, the explosion-proof battery electric transfer cart has obtained the national explosion-proof product certification.

Exhibition

BEFANBY products are sold to all over the world, such as United States, Canada, Mexico, Germany, Chile, Russia, Saudi Arabia, the United Arab Emirates, Thailand, Singapore, Indonesia, Malaysia, Australia, South Korea and other more than 90 countries and regions.

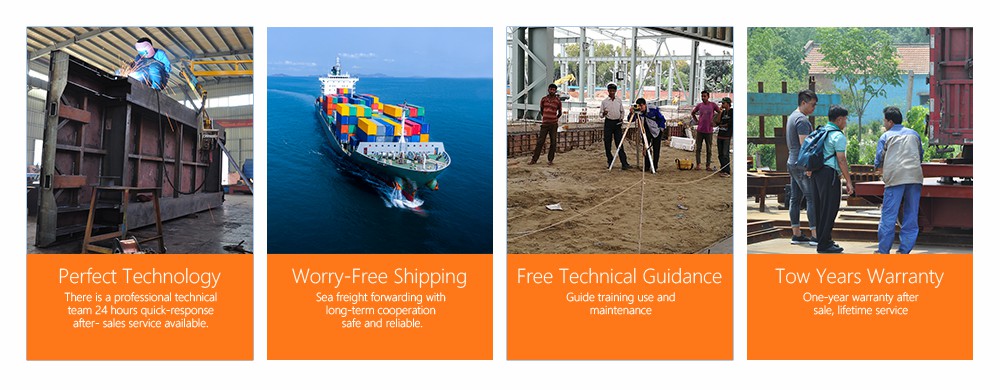

Shipping

We have long-term cooperative ocean freight forwarders, which are experienced, affordable and trustworthy. We can also customize packaging according to your requirements.