Motorized Trackless Transfer Cart

Advantage

• Reliability

Motorized trackless transfer cart with its trackless design, the cart can easily navigate through tight spaces and narrow aisles without any difficulty. This makes it particularly well-suited for use in manufacturing plants, warehouses, distribution centers, and other industrial facilities where space is at a premium.

• Safety

The trackless transfer cart also features a variety of safety features that ensure the protection of both the operator and the load being transported. It comes equipped with a range of sensors that can detect potential hazards and obstacles, such as people, walls, or equipment. This enables the cart to automatically adjust its speed or come to a complete stop if necessary, ensuring that no accidents occur during operation. Additionally, the cart comes equipped with a fail-safe braking system that automatically engages in the event of a power failure or other emergency situation.

• Versatility

It’s available in a variety of configurations to meet the specific needs of your facility. For example, it can be equipped with a variety of different control systems, including radio frequency remote control or PLC. This allows you to choose the control system that best suits your operational needs and ensures that trackless transfer cart is always operating at maximum efficiency.

• Easy Operated

It's user-friendly interface makes it easy to operate and maneuver, even for inexperienced operators. Whether you're transporting raw materials, finished goods, or heavy equipment, this cart can get the job done quickly, efficiently, and safely.

In conclusion, the motorized trackless transfer cart is a powerful and versatile material handling solution that is sure to improve the productivity and efficiency of your facility. With its advanced features, safety mechanisms, and ease of use, trackless transfer cart is the ideal choice for businesses looking to streamline their material handling operations and increase their bottom line.

Application

Technical Parameter

| Technical Parameter of BWP Series Trackless Transfer Cart | ||||||||||

| Model | BWP-2T | BWP-5T | BWP-10T | BWP-20T | BWP-30T | BWP-40T | BWP-50T | BWP-70T | BWP-100 | |

| Rated Load(T) | 2 | 5 | 10 | 20 | 30 | 40 | 50 | 70 | 100 | |

| Table Size | Length(L) | 2000 | 2200 | 2300 | 2400 | 3500 | 5000 | 5500 | 6000 | 6600 |

| Width(W) | 1500 | 2000 | 2000 | 2200 | 2200 | 2500 | 2600 | 2600 | 3000 | |

| Heigth(H) | 450 | 500 | 550 | 600 | 700 | 800 | 800 | 900 | 1200 | |

| Wheel Base(mm) | 1080 | 1650 | 1650 | 1650 | 1650 | 2000 | 2000 | 1850 | 2000 | |

| Axle Base(mm) | 1380 | 1680 | 1700 | 1850 | 2700 | 3600 | 2850 | 3500 | 4000 | |

| Wheel Dia.(mm) | Φ250 | Φ300 | Φ350 | Φ400 | Φ450 | Φ500 | Φ600 | Φ600 | Φ600 | |

| Running Speed(mm) | 0-25 | 0-25 | 0-25 | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 | 0-18 | |

| Motor Power(KW) | 2*1.2 | 2*1.5 | 2*2.2 | 2*4.5 | 2*5.5 | 2*6.3 | 2*7.5 | 2*12 | 40 | |

| Batter Capacity(Ah) | 250 | 180 | 250 | 400 | 450 | 440 | 500 | 600 | 1000 | |

| Max Wheel load(KN) | 14.4 | 25.8 | 42.6 | 77.7 | 110.4 | 142.8 | 174 | 152 | 190 | |

| Reference Wight(T) | 2.3 | 3.6 | 4.2 | 5.9 | 6.8 | 7.6 | 8 | 12.8 | 26.8 | |

| Remark: All trackless transfer carts can be customized, free design drawings. | ||||||||||

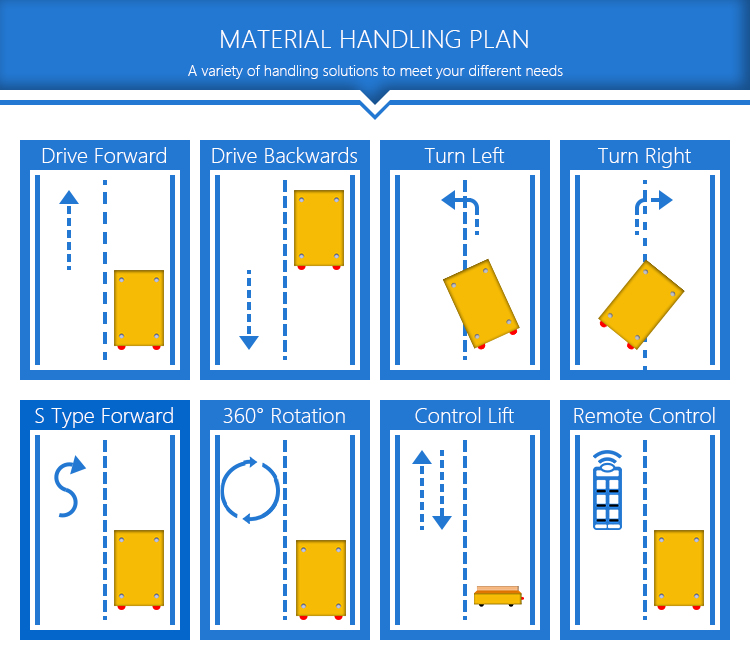

Handling methods

Handling methods