Steerable Lithium Battery Driven Automatic Guided Vehicle

This customized “Steerable Lithium Battery Driven Automatic Guided Vehicle" is based on the actual needs of customers. It combines the actual production situation of customers and the characteristics of the items to be transported to set up a trackless electric vehicle with the same size of the bracket provided by customers. Its existence can well fit the installation position of the work piece. In addition, in order to ensure safe use, a laser automatic stop device is installed in the front of the vehicle when it encounters a person. At the same time, a power display screen is installed on the electrical box to help staff control the power in real time and charge in time.

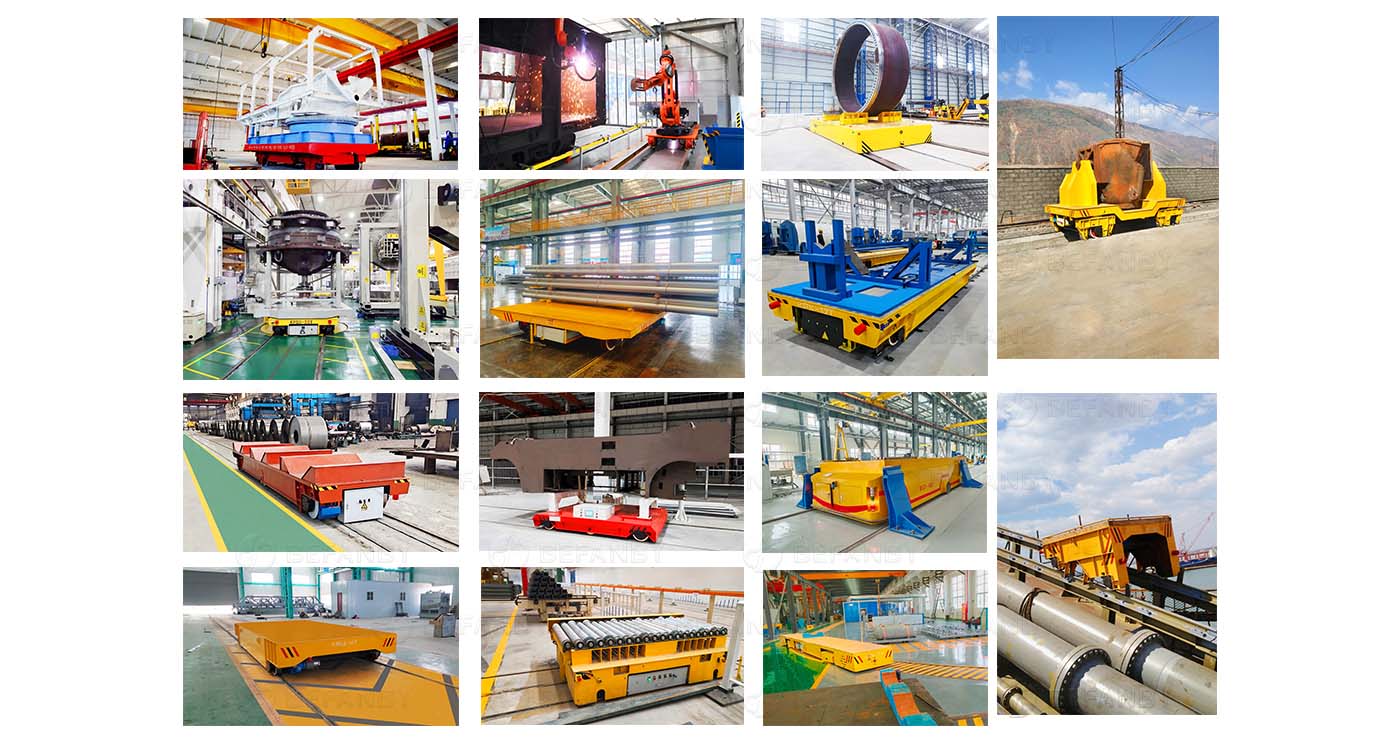

As a smart vehicle, AGV can be widely used in many occasions, such as: automatic handling and cargo sorting in logistics and warehousing, precise production line operations in mechanical processing and electronic production in manufacturing, and handling of raw materials and finished products in food and beverage industries, etc. The investment of AGV reduces human contact in the entire production process, which not only improves production efficiency but also improves the safety of the production environment.

AGV is a kind of transportation equipment that realizes autonomous movement through navigation technology. It is not only widely used but also has advantages that traditional transportation methods cannot achieve.

① High accuracy: AGV runs through navigation, and can also set the basic route of operation and determine the stop point through the PLC programming system. The accuracy can reach ±1mm, which can meet the use requirements of various production environments, especially the assembly line accuracy requirements of automobile and electronic production workshops.

② Flexible Manufacturing System (FMS): AGV can dynamically adjust the transportation path according to the actual use needs of customers (to meet the detour requirements), and can also support multi-variety, small batch, and combined production modes to improve the flexibility of the production line.

③ Rich types: The company's AGV product types are diverse, including latent, jacking, etc.

④ Remote networking: The company's AGV overcomes the need for remote networking, and can embed remote networking in the display screen. The dynamics of the car and various data can be monitored in time at home and abroad. If there is a problem, it can be directly remotely controlled, which can help customers solve after-sales problems more efficiently.

⑤ Strong technicality: The company's AGV can not only meet the basic high-temperature use needs, but also overcome the difficulties of low-temperature transportation.

AGV is intelligent and flexible, and is reshaping the operating modes in many fields such as manufacturing, logistics, and medical care, and is gradually becoming the core carrier of Industry 4.0 and smart logistics.