Steering 10T Trackless Electric Automatic Guided Vehicle

Production Details

Compared with basic models, AGV has more accessories and structures.

Accessories: In addition to the basic power device, control device and body contour, AGV uses a new power supply method, maintenance-free lithium battery. Lithium batteries avoid the trouble of regular maintenance. At the same time, both the number of charge and discharge and the volume have been newly optimized. The number of charge and discharge of lithium batteries can reach 1000+ times. The volume is reduced to 1/6-1/5 of the volume of ordinary batteries, which can improve the effective use of the vehicle's space.

Structure: In addition to adding a lifting platform to increase the working height, AGV can also be customized to add devices, such as connecting various production programs by adding rollers, racks, etc.; multiple vehicles can be operated synchronously through PLC programming control; fixed working routes can be set through navigation methods such as QR, magnetic strips, and magnetic blocks.

On-site Display

As can be seen from the picture, this AGV is controlled by a wired handle. Emergency stop devices are installed at the four corners of the vehicle, which can respond as quickly as possible to reduce work risks in an emergency. At the same time, safety edges are installed in front and behind the vehicle body to greatly improve the safety of the workplace. The vehicle is used in the production workshop. It can move flexibly without the restriction of tracks and can even rotate 360 degrees.

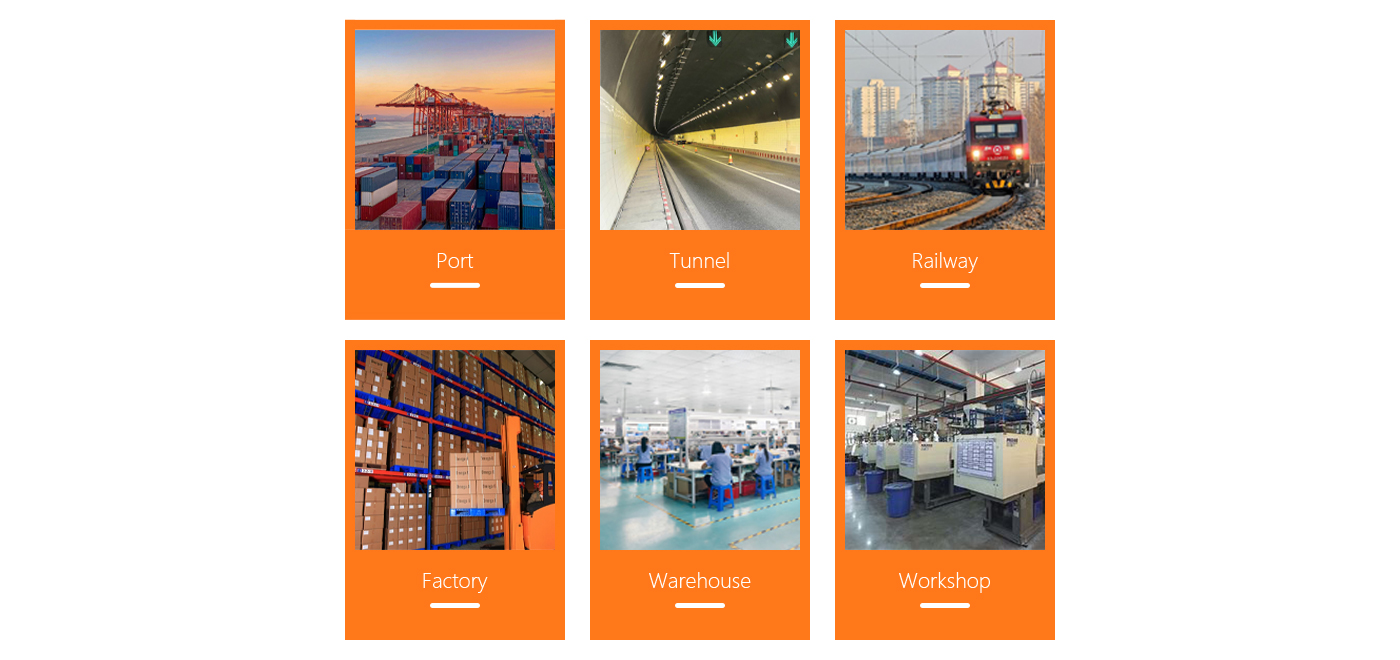

Applications

AGV has the advantages of no use distance limit, high temperature resistance, explosion-proof, flexible operation, etc., and can be widely used in a variety of industrial sites, warehouses, and production processes. In addition, the operation site of AGV needs to meet a condition that the ground is flat and hard, because the high-elasticity wheels used by AGV may get stuck if the ground is low or muddy, and the friction is insufficient, causing the work to stagnate, which not only hinders the progress of the task but also damages the wheels and requires frequent replacement.

Customized For You

As a product of customized services, AGV vehicles can provide a full range of customized design services, from color and size to functional table design, safety configuration installation, navigation mode selection, etc. In addition, AGV vehicles can also be equipped with automatic charging piles, which can be set by PLC program to perform timed charging, which can effectively avoid the situation where staff forget to charge due to carelessness. AGV vehicles came into being with the pursuit of intelligence, and are constantly exploring ways to meet the needs of the times and transportation needs.